How to Select and Maintain the Optimal Steel Belt for Your Industrial Cooling and Flaking Process

In industries ranging from chemical processing to food production, the efficiency of cooling, flaking, and conveying operations hinges on one critical component: the Steel Belt. Selecting the right belt and implementing a robust maintenance protocol are not just operational details—they are strategic decisions that impact productivity, product quality, and total cost of ownership. This comprehensive how-to guide, presented by Shanghai Biquick Process Systems Ltd. (BPS/EPS), will walk you through the essential steps to make informed choices and ensure the longevity of your steel belt systems.

Why This Guide Matters

With over 40 dedicated professionals and a mission to "Based in China and serve globally," BPS/EPS has established itself as a pioneer in integrated solutions for steel belt transmission-based manufacturing. Our expertise spans from supplying high-performance carbon steel belts and stainless steel belts to designing complete systems like the Sulphur Pastillator and Epoxy Steel Belt Cooler. This guide distills our years of hands-on experience into actionable knowledge for plant managers and engineers worldwide.

Step 1: Defining Your Application Requirements

The first and most crucial step is a thorough analysis of your process. The wrong belt material or specification can lead to premature failure, contamination, or inefficient operation.

- Process Type: Is it a cooling, flaking, baking, or conveying application? For instance, a Double-belt resin cooling flaker demands excellent thermal conductivity and flatness, while a Chocolate Steel Belt Conveyor requires a hygienic, easy-to-clean surface.

- Material Characteristics: Consider the temperature (hot-melt materials for a powder painting Steel Belt Flaker), acidity, abrasiveness, and adhesion properties of the product being processed.

- Environmental Factors: Will the belt be exposed to moisture, steam (as in a Steel belt Steam oven), or cleaning chemicals? This dictates the need for corrosion-resistant Stainless steel belts.

- Physical Demands: Assess the required tensile strength, wear resistance, and need for special features like perforations for drainage or PTFE coating for non-stick properties.

Consulting with an expert provider like BPS/EPS at this stage is invaluable. We help translate your process needs into precise technical specifications.

Step 2: Choosing the Right Steel Belt Type and Configuration

Based on your requirements, you can navigate the core options:

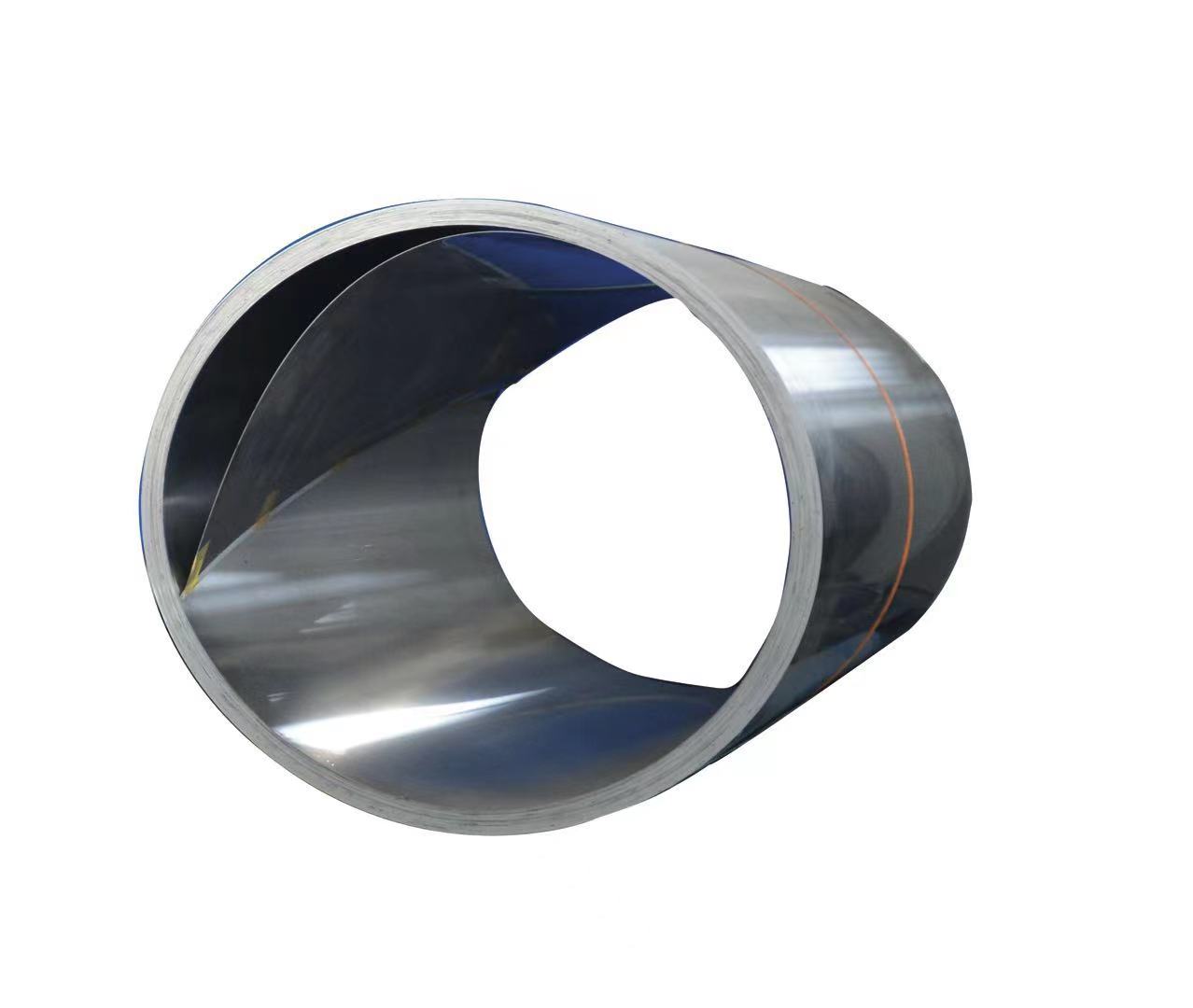

Carbon Steel Belts

Ideal for applications with excellent thermal performance needs and low corrosion risk. Perfect for Steel belt bakery tunnel Ovens, drying pastes, or processes involving heating and baking. They offer very good static/fatigue strength and wear resistance.

High-quality carbon belts from BPS/EPS

Stainless Steel Belts

The choice for hygienic processing and corrosive environments. Essential for food lines like Steamed cake production lines or Crab stick molding machines, and for chemical coolers like the Polyester Steel Belt Cooler. They provide outstanding corrosion resistance and strength.

Durable Stainless steel belts for hygienic applications

Configuration Choices:

- Form: Open-length belts for on-site welding or endless pre-welded belts.

- Surface: Plain, perforated, or with custom finishes like casting coating.

- Accessories: Integration of rubber V-ropes for tracking, retaining strips, or transverse flights for incline conveying.

Step 3: Implementing a Proactive Maintenance Regimen

Even the highest-quality belt requires care. A proactive approach prevents costly downtime.

Routine Inspection Checklist:

- Tracking: Ensure the belt runs centrally to avoid edge damage.

- Tension: Check and adjust to manufacturer (BPS/EPS) specifications. Incorrect tension is a major cause of press steel belt failure.

- Surface Condition: Look for signs of wear, scratches, or material buildup. For Frible Steel belts or belts with special coatings, this is critical.

- Joints & Edges: Inspect welds or riveted joints and belt edges for cracks or fraying.

- Support System: Check rollers, drives, and bearings for alignment and smooth operation.

Professional Steel belt cracks welding repair service by BPS/EPS

Cleaning and Lubrication:

Follow a cleaning schedule compatible with your belt material and product. Use recommended lubricants for drive sprockets to prevent wear on electric steel belt drives.

Step 4: Knowing When and How to Repair or Replace

Addressing issues early is key. BPS/EPS offers comprehensive after-sales services to support you.

- Minor Repairs: Small cracks or localized wear can often be repaired via professional steel belt insert repair or welding, restoring the belt's integrity.

- Major Damage or Wear: Extensive cracking, thinning, or permanent deformation usually necessitates replacement. Partner with your supplier for a seamless steel belt replacement and installation process.

- Accessory Service: Don't neglect components like rubber V-ropes. BPS/EPS provides bonding and replacement services to maintain optimal tracking.

Leverage the expertise of your supplier. BPS/EPS maintains a service center in Shanghai offering emergency maintenance, installation guide, and operation training to protect your long-term investment.

The BPS/EPS Advantage: Your Partner in Steel Belt Solutions

Choosing Shanghai Biquick Process Systems Ltd. (BPS/EPS) means more than buying a belt; it's partnering for total process success. Our integrated approach covers:

- Total Solutions: From standalone Steel Belts to complete systems like Wax pastillors and Single-belt resin flakers.

- Quality Assurance: Our manufacturing processes are backed by ISO 9001:2000 and ISO 14001:2004 certifications, ensuring reliability and environmental responsibility.

- Global Support: With headquarters in Shanghai and offices across China, we are positioned to serve globally. Our team provides end-to-end support from selection to post-service.

Ready to optimize your steel belt system? Contact the experts at BPS/EPS today.

Phone: +86-13916661495 / +86-21-68904153

Email: ken.feng@bpstek.com / sales@bpstek.com

Website: www.bpstek.com

Address: No.172 Xuanchun Road, Xuanqiao Town, Pudong New District, Shanghai, China.

By following this structured guide, you can significantly enhance the performance and lifespan of your Steel Belt equipment, whether it's a critical Epoxy Steel Belt Cooler or a high-volume Steamed cake production line. Informed selection and diligent maintenance are your pathways to reduced downtime, consistent product quality, and a stronger bottom line.