The Definitive Guide to Procuring High-Performance Steel Belt Systems

In today's competitive industrial landscape, selecting the right Steel Belts and associated processing equipment is not merely a purchase—it's a strategic investment in production efficiency, product quality, and long-term operational reliability. Whether you are involved in chemical pastillation, food processing, resin cooling, or bakery automation, the core of your continuous production line often hinges on the performance of your steel belt system. This comprehensive buyer's guide, leveraging insights from industry leader BPS/EPS, is designed to navigate you through the critical considerations, technological nuances, and selection criteria for Stainless steel belts, carbon belts, and specialized equipment like Sulphur Pastillators and Steel belt bakery tunnel Ovens.

Why This Guide Matters

The global push for higher automation, stringent hygiene standards (especially in food and pharmaceuticals), and the need for energy-efficient cooling and heating processes have elevated the importance of precision-engineered steel belt solutions. A suboptimal choice can lead to frequent downtime, inconsistent product quality (e.g., uneven flake thickness from a powder painting Steel Belt Flaker), and higher total cost of ownership.

Chapter 1: Understanding Your Core Needs – The Application Matrix

Your selection journey begins with a clear understanding of your application. Steel Belts are not one-size-fits-all.

| Application | Recommended Belt Type | Key Equipment | Critical Performance Factors |

|---|---|---|---|

| Chemical Pastillation (Sulphur, Wax) | High-grade Stainless steel belts with excellent thermal conductivity and corrosion resistance. | Sulphur Pastillator, Wax pastillor | Rapid, uniform cooling; precise droplet control; belt surface finish for easy release. |

| Resin/Polymer Cooling & Flaking | Precision-ground carbon belts or Stainless steel belts for high thermal stress. | Epoxy Steel Belt Cooler, Polyester Steel Belt Cooler, Single-belt resin flaker, Double-belt resin cooling flaker | Controlled cooling rate for crystal structure; adjustable thickness; crushing consistency. |

| Food Baking & Steaming | Food-grade Stainless steel belts (AISI 304/316), often perforated for steam/air flow. | Steel belt bakery tunnel Oven, Steel belt Steam oven, Steamed cake production line | Hygienic, easy-clean surface; even heat distribution; durability under thermal cycling. |

| Food Molding & Conveying | Highly polished Stainless steel belts or PTFE coating steel belts for non-stick properties. | Chocolate Steel Belt Conveyor, Crab stick molding machine | Precise tracking; gentle product handling; corrosion resistance to food acids/salts. |

| Panel Pressing & Special Coatings | High-strength, heat-resistant carbon belts or specially treated press steel belts. | - | Exceptional flatness (Frible Steel belts for minimal deflection); high pressure/temperature tolerance; surface finish for casting coating steel belts. |

Chapter 2: The Steel Belt Deep Dive – Material and Design Selection

Choosing between carbon steel belts and Stainless steel belts is fundamental.

Carbon Steel Belts

Best For: Applications requiring superior thermal conductivity and static/fatigue strength in non-corrosive or controlled environments. Ideal for Steel belt bakery tunnel Ovens, drying processes, and press steel belts for panel production like wood OSB press belts.

- Pros: Excellent thermal properties, high wear resistance, good repairability, cost-effective for high-temperature operations.

- Cons: Prone to corrosion if not properly maintained; requires protective atmosphere in some ovens.

- Key Spec: Look for heat-treated steel with a hard, smooth surface and dark oxide layer.

Stainless Steel Belts

Best For: Hygienic, corrosive, or wet environments. The default choice for food (Chocolate Steel Belt Conveyor, Steamed cake production line), chemical (Sulphur Pastillator), and pharmaceutical applications.

- Pros: Outstanding corrosion resistance, high strength-to-weight ratio, hygienic easy-clean surface, aesthetic appearance.

- Cons: Generally higher initial cost; slightly lower thermal conductivity than carbon steel.

- Key Spec: Austenitic chromium-nickel (304/316) grades, with cold-working for enhanced strength.

Design Considerations: Beyond material, consider Perforated belts for airflow, electric steel belts for integrated heating, custom surfaces (polished, textured, PTFE coating steel belts), and tracking aids like integrated rubber V-ropes.

Chapter 3: Equipment Selection – Matching Technology to Process

The belt is the heart, but the equipment is the body. Here’s how to choose.

1. For Cooling and Solidification: Pastillators and Flakers

Sulphur Pastillator / Wax pastillor: Evaluate based on:

- Cooling Efficiency: Look for a design that sprays water directly on the belt's backside for rapid, uniform cooling and recyclable water.

- Deposition Control: Ensures uniform droplet size and shape.

- Adaptability: Can it handle varying viscosities of your molten material?

Resin/Powder Flakers (Epoxy Steel Belt Cooler, Polyester Steel Belt Cooler, powder painting Steel Belt Flaker): Key selection points:

- Cooling Zone Configuration: Single-belt resin flaker vs. Double-belt resin cooling flaker (for higher capacity or double-sided cooling).

- Adjustability: Precision controls for flake thickness and final crush size.

- Hygiene & Cleanability: Critical for product purity; stainless steel construction is preferred.

2. For Thermal Processing: Ovens and Steamers

Steel belt bakery tunnel Oven: For continuous production of bread, cakes, cookies. Prioritize:

- Zoned Temperature Control: For precise baking profiles.

- Heat Distribution Uniformity: To avoid uneven browning.

- Belt Tracking Stability: Prevents belt drift and damage.

- Customization: Can the supplier tailor width, length, and heating sources to your line?

Chapter 4: The Supplier Evaluation Checklist – Beyond the Product

Your partner is as important as the product. Here’s what to look for in a supplier like BPS/EPS:

- Technical Expertise & Solution Offering: Do they offer total solutions—from the belt to the complete machine (Chocolate Steel Belt Conveyor, Sulphur Pastillator) and process control advice?

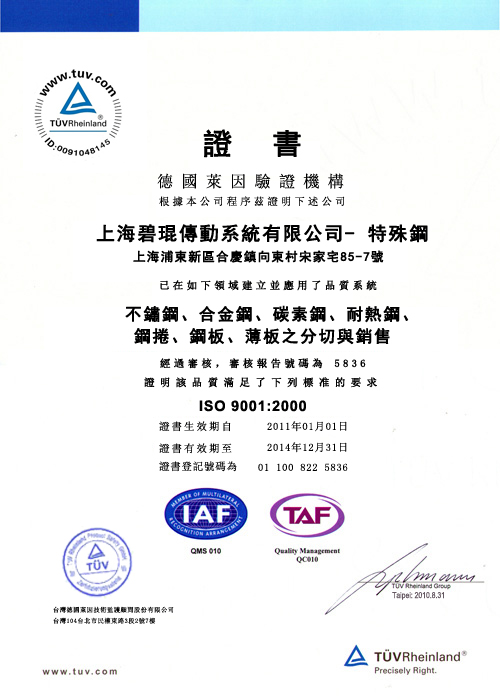

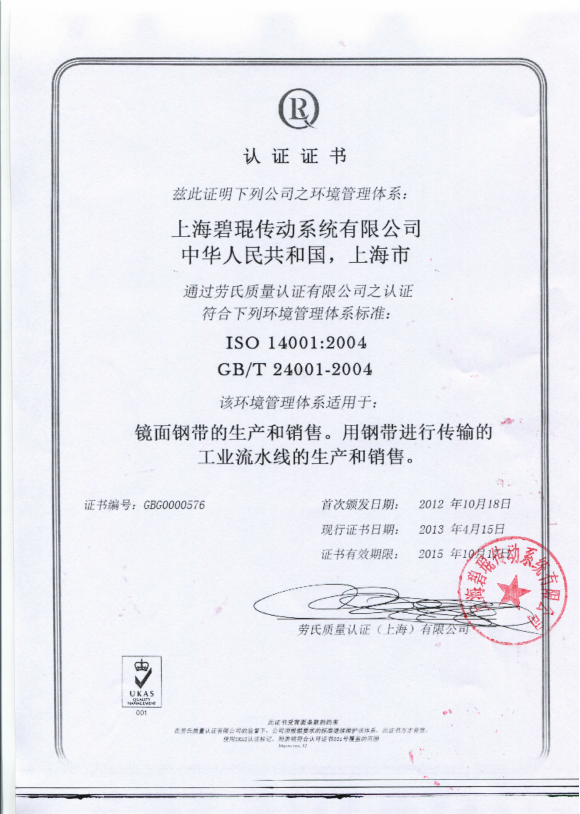

- Manufacturing & Quality Control: Inquire about their tolerances (e.g., thickness ±0.045 mm), material sourcing, and quality certifications.

- After-Sales & Service Network: This is critical for Steel Belts which are long-term assets. Verify:

- Availability of Spare Parts: For electric steel belts or drive components.

- Maintenance & Repair Services: Can they perform Steel belts cracks Welding repair or insert repair on-site or at their service center?

- Technical Support: Do they provide installation guidance, operational training, and emergency support?

- Global Reach & Local Presence: A supplier like BPS/EPS, with its mission "Based in China and serve globally," and offices in Shanghai, Beijing, Guangzhou, etc., offers both cost efficiency and local support.

Chapter 5: Making the Decision – Total Cost of Ownership (TCO)

Do not decide on initial price alone. Calculate the TCO over a 5-10 year period:

- Initial Investment: Cost of belt (carbon belts vs. Stainless steel belts) and equipment.

- Operational Costs: Energy efficiency of the Steel belt Steam oven or cooling system, labor for operation.

- Maintenance & Downtime Costs: Frequency of repairs, ease of Equipment Maintenance and Repair, cost of spare parts.

- Productivity & Quality Gains: Higher output from a Double-belt resin cooling flaker, reduced waste from precise control.

A slightly higher investment in a premium Stainless steel belt from a reputable supplier often pays for itself through years of reliable, trouble-free service.

Ready to Specify Your Steel Belt System?

Armed with this guide, you are now prepared to engage with suppliers knowledgeably. For tailored advice on your specific application involving Steel Belts, Sulphur Pastillators, Epoxy Steel Belt Coolers, or Steel belt bakery tunnel Ovens, contact the experts at BPS/EPS.

Visit: www.bpstek.com

Email: ken.feng@bpstek.com / sales@bpstek.com

Phone: +86-13916661495 / +86-21-68904153

Address: No.172 Xuanchun Road, Xuanqiao Town, Pudong New District, Shanghai, China

Invest wisely in the backbone of your continuous process line.